Power

Temperature and pressure instruments for power equipment and systems

Applications of Measurement and Monitoring Technology

Today, the global power industry is faced with the challenge of developing a solution that accommodates the rising demand for a reliable and flexible source of energy without increasing operational emissions or costs. One method industry professionals rely on to achieve and maintain effective and efficient operations is integrating temperature and pressure instruments into their power generation and distribution equipment. This measurement and monitoring technology allows them to identify if and when their systems require modifications to improve their performance.

At Ashcroft, our measuring and monitoring solutions find application in a variety of power generation and distribution equipment, including, but not limited to, the following:

Gas-fired power plants operate under stringent regulations due to volatile, high-risk conditions. Pressure monitoring is critical for turbine and steam generation operations, while boilers, combustion, denitrification, and heat recovery systems must be closely watched for temperature fluctuations. Our 5503 and 5509 differential pressures units are ideal for applications involving low in. H2O differential or high static pressures. They feature an all stainless steel construction and IP 65 Ingress protection class rating for safe and reliable performance.

Coal-fired power plants, a traditional mainstay of the power industry, have evolved to meet growing customer demand and increasingly strict emissions standards. They rely on temperature and pressure monitoring equipment to ensure they maintain efficient power usage and acceptable emission rates.

Nuclear power has long been a contentious subject. Public acceptance and economic viability of nuclear as a power source are largely dependent on monitoring technology. Precise monitoring of pressure and temperature in nuclear power plant operations can enhance operational stability and efficiency and provide real-time data for process improvement.

Sustainable energy systems (e.g., hydropower and wind turbines) utilize measurement and monitoring instruments to control fluid pressure and levels. For example, pressure transducers and switches are used to monitor hydraulic pressure in accumulators, while level switches are used to monitor hydraulic fluid levels in wind turbine reservoirs.

Gas turbines rely on pressure sensors and switches to ensure fuel levels and pressures remain optimal for system performance.

Boilers generate high levels of heat and pressure, both of which can have explosive consequences if left unchecked. As a result, they are subject to strict regulatory standards to ensure they maintain safe operating conditions. Pressure and temperature instruments—e.g., switches—are positioned strategically throughout boiler systems to ensure they run properly and safely.

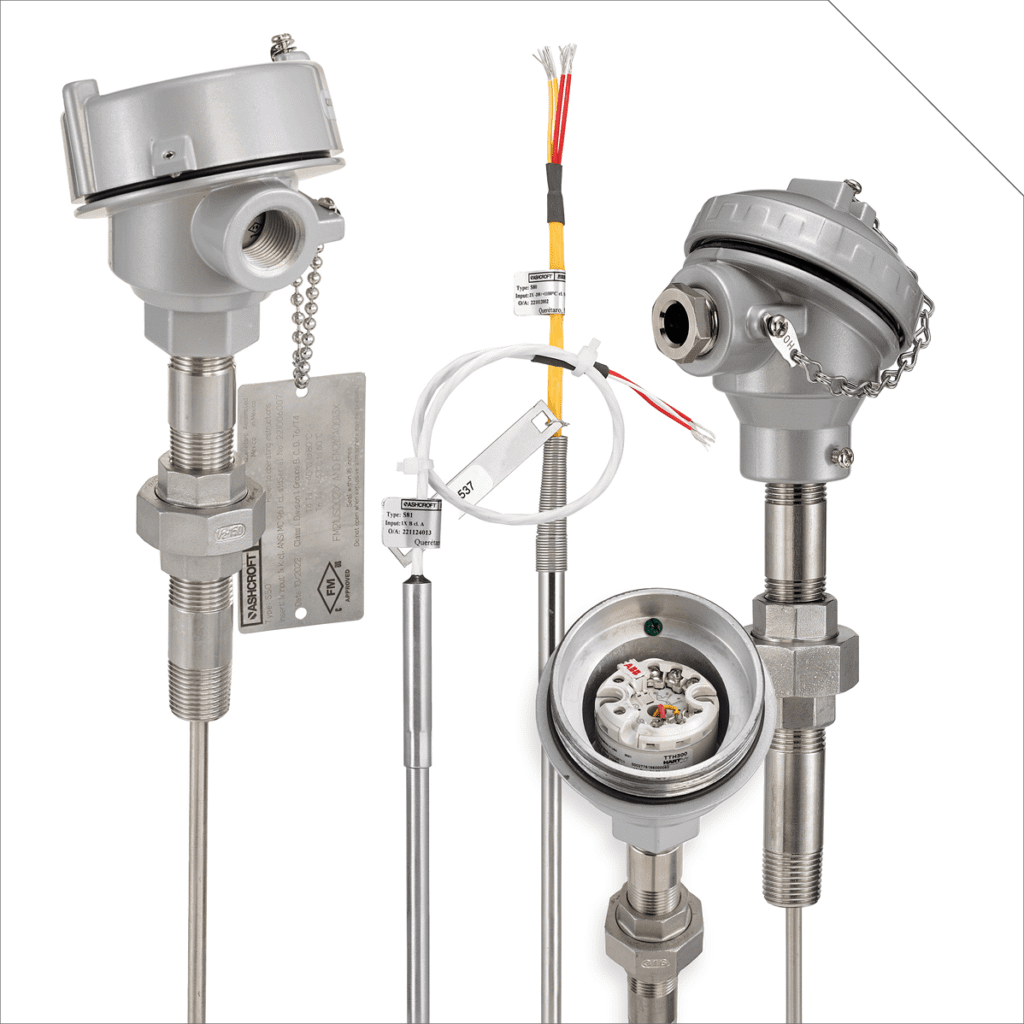

Heat recovery system generators are elements used in small-scale and localized power generation facilities to create additional power. We offer rugged and reliable RTDs, tube skin thermocouples, and other temperature and pressure instruments that allow these systems to work properly.

Ashcroft: Your Single-Source Solution

At Ashcroft, we offer measurement and control instruments suitable for use in power equipment and systems, ranging from large-scale, on-the-grid power plants to individual, off-the-grid power stations. Over our 165 years in business, we’ve earned the trust of industry professionals across the world with our quality products and services.

Our focus on safety drives us to ensure our instruments protect people, processes and profits. Additionally, we strive to develop innovative solutions that provide protection in all areas of the plant, even for the most critical processes and applications. Equipped with extensive engineering experience and market knowledge, we can design, develop, manufacture, test, and calibrate instrument solutions tailored to virtually any customer need. For example, we supply resistance thermometer detectors (RTDs) and thermocouples for heaters, generators, pumping stations, and other power system elements.

Importance of Measurement and Monitoring Technology for the Power Industry

As indicated above, power industry professionals are challenged to find a way to establish a dependable, eco-friendly, and low-cost energy supply that meets the rapidly growing consumer demand. Measurement and monitoring instruments help bring them closer to overcoming this challenge by ensuring power equipment achieves and maintains optimal performance. However, the technology employed must be durable and reliable enough to withstand the harsh operating conditions characteristic of power generation and distribution facilities.

By integrating our high-quality temperature and pressure instruments in power equipment, industry professionals benefit from the following:

Better compliance with industry/regulatory requirements

Many power generation and distribution operations are highly volatile. As such, it is essential to ensure operating conditions—e.g., temperature and pressure—remain within appropriate ranges set by industry and regulatory standards. Otherwise, there is a high risk of employee injury or environmental damage. Measurement and monitoring technology enable system operators to detect anomalies in system performance and implement an appropriate solution before a catastrophe occurs. For example, resistance temperature detectors (RTDs) and thermocouples help industry professionals keep temperatures within power generation and distribution equipment at safe levels.

Greater operational effectiveness and efficiency

Pressure and temperature instruments, such as differential pressure (DP) gauges, switches, and temperature sensors, allow system operators to determine if and when system performance is optimal. By carefully measuring and monitoring system conditions, they can make appropriate changes to ensure the system runs effectively and efficiently.

Higher cost savings

Both better compliance with industry/regulatory standards and greater operational effectiveness and efficiency translates to higher cost savings. A system with optimal performance uses less energy than one with suboptimal performance, resulting in lower energy costs. A system that complies with all relevant industry/regulatory standards is less likely to bring about lawsuits or fines than a non-compliant one.

Why Partner with Ashcroft?

Your single-source solution provider. At Ashcroft, we are a premier source of temperature and pressure measurement and control solutions for customers across a wide range of industries. We offer sensors, switches, gauges, transducers, and other instruments that allow industrial equipment—including power generation and distribution systems—to operate efficiently, reliably, and safely. By partnering with us for their instrument needs, power industry professionals benefit from our:

Our over 165 years in business has given us a comprehensive understanding of industrial applications and processes. This insight allows us to develop instruments to the exact needs of the power facility, ensuring it runs efficiently, cleanly, and consistently.

Our extensive experience enables us to identify potential opportunities for optimization within a power facility. By implementing these recommendations, industry professionals can experience better system performance, lower energy costs, and greener operations.

Our products are compliant with/approved by numerous national and international standards, including ISO 9001, ATEX, CE, UL, and FM. However, our team continually looks for ways to improve our products and processes even further.

Our advanced instruments—e.g., our pressure gauges and switches—are engineered to offer reliable performance even under extreme conditions. For example, they can be made from compatible wetted material for application environments with corrosive pressure media or constructed in agency-approved, explosion-proof designs for hazardous environments.

Trust in the Ashcroft Experts

At Ashcroft, we are here to help you identify the right temperature and pressure instruments and understand how they can benefit your power generation or distribution facility. For product solutions that matter most to your critical applications, you can trust us with the success and safety of your project.