Pharmaceutical and Biotech

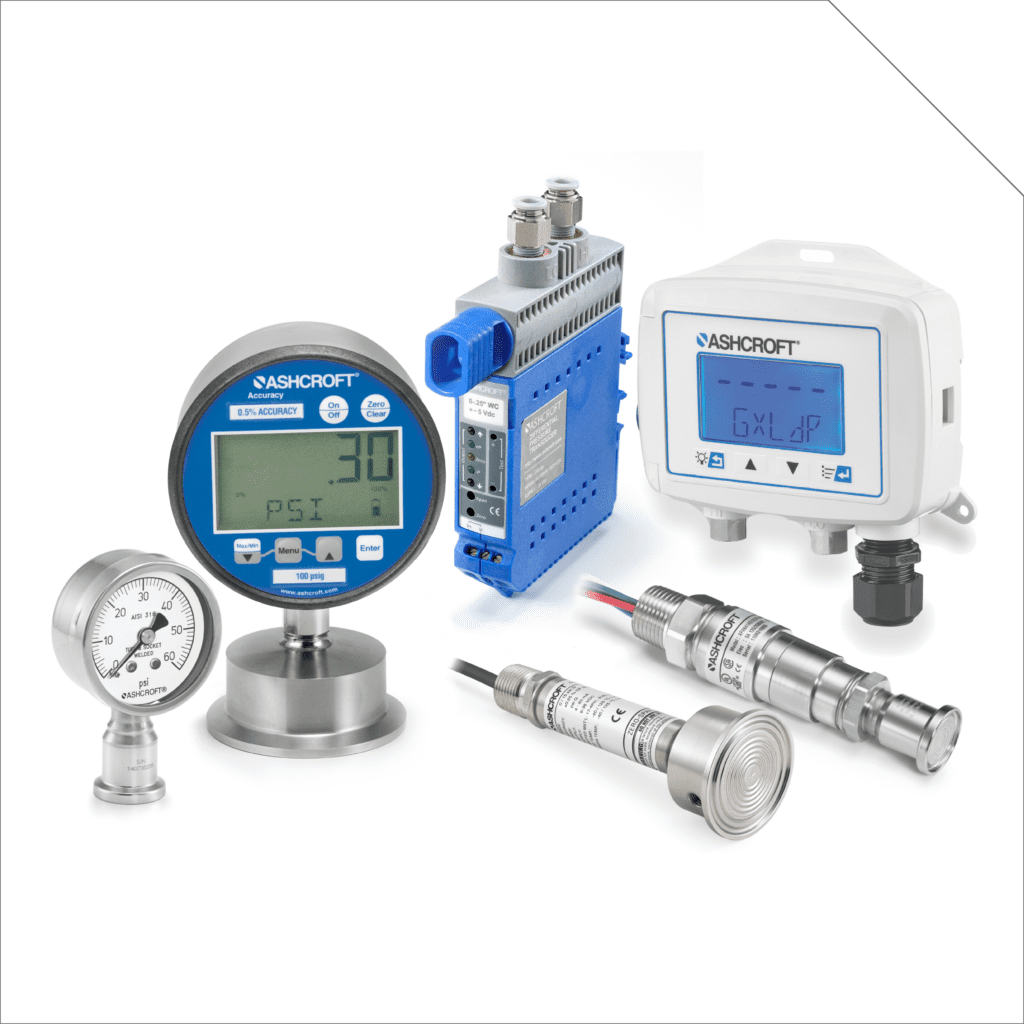

Pressure and temperature instruments for pharmaceutical and biotechnology industries

Applications of Measurement and Monitoring Technology

In the pharmaceutical and biotechnology industries, strict control over facility conditions is essential to preventing product contamination and, consequently, ensuring product integrity. For this reason, many pharmaceutical and biotechnology companies utilize cleanrooms when developing and manufacturing their products to protect the health and well-being of consumers. The performance of these systems relies on accurate and reliable instrumentation, which allows developers and manufacturers to achieve and maintain the conditions needed to accommodate product specifications and industry and regulatory standards.

At Ashcroft, our pressure and temperature instrument solutions are employed in a wide range of pharmaceutical and biotechnology applications, such as:

Our pressure measuring and monitoring instruments help ensure the pressure within cleanrooms and other critical environments remain at optimal levels. We provide solutions that offer ultra-low pressure measurement capacities, in-place calibration and monitoring capabilities, and traceable calibration certificate.

Our instruments are highly sensitive and accurate, demonstrating low-pressure monitoring capabilities for compounds ranging from flammable vapors to toxic fumes. They feature ultra-low range with high proof pressure capabilities, NIST traceable certification, and an LED status indicator.

Pharmaceutical and biotechnology operations demand compliance with strict sanitation standards to ensure products remain uncontaminated. We provide measurement and control solutions engineered with hygienic design in mind. They feature electropolished stainless steel wetted material, Tri-clamp™ connections that comply with 3-A sanitary standard 74-07, and SIP/CIP capacities.

We offer high-accuracy instruments that help achieve and maintain the right conditions during highly automated batch processes. Our Critical Application Solution Experts® (CASE®) help identify which of our all-welded gauges, isolation devices, and other instrument offerings are right for a customer’s custom solution.

Importance of Measurement and Monitoring Technology for the Pharmaceutical and Biotechnology Industries

At Ashcroft, we specialize in the development, engineering, manufacturing, testing, and calibration of pressure and temperature instruments. Our measurement and monitoring solutions are custom-tailored to the unique requirements and restrictions of the intended industry and industrial application, ensuring each customer receives instrumentation that fully meets their needs. For the pharmaceutical and biotechnology industries, we offer ultra-accurate, ultra-reliable instruments that facilitate effective and efficient cleanroom performance.

By integrating our measurement and monitoring solutions into their cleanrooms, pharmaceutical and biotechnology companies benefit in several ways, including the following:

- Compliance with regulatory standards. Our pressure and temperature instruments help industry professionals ensure their cleanroom facilities and equipment comply with industry and regulatory standards regarding precision, sanitation, and safety. As a result, they have better conditions for researching, developing, and producing medicines and other potentially life-saving products.

- Process optimization. Our pressure, temperature, and level sensors can be configured to signal alarms when equipment conditions fall outside the acceptable range. This function helps industry professionals keep their systems in check and their processes consistent as well as identify if and when they can be improved or optimized.

- Cost savings. Our instrumentation helps protect our customers’ people, processes, and profits, which can lead to lower overall operational and maintenance costs and greater return on investment (ROI).

Ashcroft Instruments for the Pharmaceutical and Biotechnology Industries

At Ashcroft, we strive to make cleanrooms cleaner with innovative instrument solutions. Our instrumentation offerings include:

- Our advanced transducers offer ultra-low to high-range measurement capabilities. They feature our SpoolCal® technology, which is ideal for proactive maintenance as it allows for in-place calibration, validation, and monitoring. They are often used in HVAC systems to help monitor and control conditions (e.g., pressure and airflow) in sterile environments.

- Our all-stainless steel gauges are designed specifically for use in pharmaceutical, biotechnology, and food processing applications. Our model 1036 gauge and model 1037 instrument fitting assembled together eliminates the risk of deadleg or pocket formation that can lead to contamination.

In addition to our standard instrument offerings, we also offer sanitary instruments designed for use in sterile environments. Our sanitary pressure gauges and temperature sensors are built to accommodate clean-in-place (CIP) and sterilize-in-place (SIP) operations, both of which are standard requirements for the pharmaceutical and biotechnology industries. We also offer autoclave capabilities for our instrument solutions.

Why Partner with Ashcroft?

At Ashcroft, we design, develop, and deliver temperature and pressure instrumentation for a wide range of industrial applications and processes. By choosing us as their source for instrument solutions, pharmaceutical and biotechnology industry professionals benefit from our:

We’ve provided tens of thousands of instrument solutions to pharmaceutical facilities, data centers, hospitals, and other critical care environments where uncompromised performance is essential. This experience gives us the knowledge and skills to design and manufacture accurate and reliable instrumentation that fully accommodates customer specifications and industry/regulatory standards.

Our instruments are compliant with and approved by a number of national and international standards, including ISO 9001, 3-A, ATEX, NIST, CE, UL, and FM. They integrate a variety of advanced measurement and control technology. For example, we offer low differential pressure (DP) transducers calibrated to our TruAccuracy™ specification, which takes into account both zero and span tolerance. They have a highly reliable variable capacitance sensor that uses our patented Si-Glas™ sensor, which has an ultra-thin single-crystal diaphragm that allows for better sensor stability and repeatability. They also feature our SpoolCal design, which allows for in-place calibration and certification operations.

We provide instruments designed and built for ease of use. For example, our low DP sensors come with snap track mounts, removable terminal strips, and options for our SpoolCal® design. They feature electropolished stainless steel wetted material, sanitary Tri-Clamp connections, and SIP/CIP capabilities, which make them well-suited for use in sterile environments.

Our extensive experience providing instrument solutions for pharmaceutical and biotechnology applications allows us to easily identify areas that need improvement and/or optimization and provide appropriate recommendations.

Trust in the Ashcroft Experts

At Ashcroft, we are here to help you identify the right pressure and temperature instruments and understand how they can benefit your cleanroom operation. For product solutions that matter most to your critical applications, you can trust Ashcroft with the success and safety of your project.